Gold Wire Bonding Machine

It uses force power time temperature up to 150 c and ultrasonic energy.

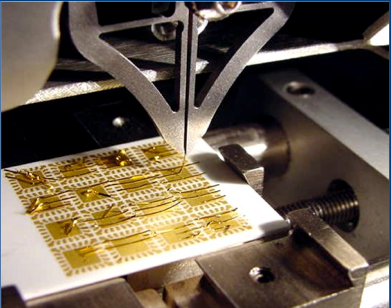

Gold wire bonding machine. Typical applications for wire wire bonders are components in hf and rf technology cob mcm hybrids optical and automotive electronics. The technician needs to prepare and sets the capillary and the gold wire into machine. This method is commonly known as thermosonic gold ball wire bonding. The winding reel has a plate type clutch with ring gear and adjustable ring nut on the transmission that permits gradual start up of the machine to prevent the wire from breaking.

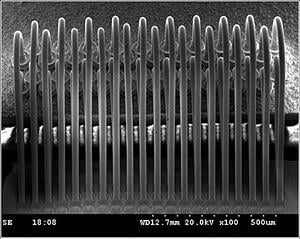

Heraeus offers a wide selection of gold ball bonding wires in a full range of diameters to suit your applications from high power and discrete components to high pin count ultra fine pitch devices. The bondjet bj855 meets the increasing demands of wire bonding and contributes to easy porting through smart functions such as the bondhead memory or the chip libraries. Within three major classifications of heraeus ball bonding gold wires the right wire can be found for any ball bonding application. We manufacture wire bonders die bonders die attach epoxy die attach pull tester and shear tester for the semiconductor industry.

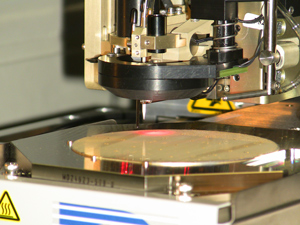

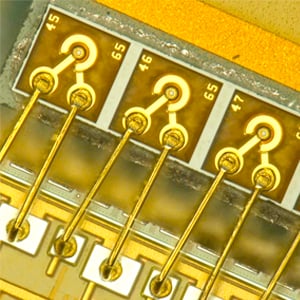

Kulicke soffa k s are the world leaders for automatic wire bonders. The machine frame has a cast iron support a metal base and a heavy duty cast iron drawing roller. Gold ball wire bonding and stitch bonding is the most widely used assembly process in the semiconductor industry to interconnect the die circuitry to the package or substrate. Levels of automation vary from completely manual to fully automatic.

Ball bonding is a type of wire bonding and is the most common way to make the electrical interconnections between a chip and the outside world as part of semiconductor device fabrication. If copper wire is used nitrogen must be used as a cover gas to prevent the copper. The most common approach in thermosonic bonding is to ball bond to the chip then stitch bond to the substrate. Technician needs to program the pattern into the wire bonding machine system.

Wire bonding wedge bonding ball bonding bump bonding. Next the technician needs to set the parameter of wire bonding machine and used the dummy of the lead frame which have the die for setting. Then he needs to load the dummy. Gold or copper wire can be used though gold is more common because its oxide is not as problematic in making a weld.